The term fracking conjures up so many knee-jerk-bad reactions that I am hesitant to broach the subject. I suppose if I am going to wade into the topic I should give some bona fides to display my knowledge of the petroleum industry, but not too many bona fides so that I might be seen as a talking wonk for the gas industry. I worked for one year as an engineer for a well service company called Schlumberger (world’s largest) and two as a geologist with Shell Oil. Shell gave its geologists full responsibility for drilling a well from the time it was proposed to production if it hit oil. Of the 11 wells I proposed, 3 hit oil which was above the industry standard in producing fields in the late 1970s and early 1980s. Eventually I realized my calling was in teaching and research and left to go back to school for my PhD. But not before I got a pretty good idea of how the industry works.

The process of drilling is not complicated although the devil can be in the details. A rig contains strings of thirty-foot drill pipe which attach to a tri-cone tungsten carbide bit (see the image below). The bit spins from drives or motors as drilling fluid, called mud (contents vary but clay, water and lubricants are typical), is pumped through the pipe string to keep the bit cool, increase pressure, and bring the rock debris from drilling back to the surface along the outside of the pipe. One of the technological marvels developed in modern times is the ability to direct the drill bit to specific locations with pin-point accuracy by knowing where the bit is in three-dimensional space usually thousands of feet below the surface. Directional survey measurements are complex but are based on measurements while drilling through various instruments. These advances have enabled horizontal drilling which has become important in fracking.

Rama, Wikipedia

Rama, Wikipedia

I would be remiss not to emphasize the importance given to protecting the water table when drilling. State and Federal regulations require the well to be sealed off at least 50 feet below where potable groundwater can be produced, and those laws have been in place as far back as anyone can remember. The drill pipe is tripped (pulled completely out of the hole) when regulators deem the surface casing should be set to protect the water table (something on the order of 500 feet usually). The casing is cemented in place, and if it is done correctly, we know from the drilling of hundreds of thousands of wells over many decades that the water table is protected. After the surface casing is set, drilling is continued until the target zone is reached. The pipe is tripped again and the entire well is generally set with cemented production casing. The hole is plugged at the bottom usually up to 50 feet below the horizon of interest. The casing is perforated by tools that blow holes in it precisely where the rock containing oil and/or gas exists. Lisa Margonelli has written an excellent book entitled Oil On the Brain about the details of drilling and its impact on the politics of many countries like Nigeria and Venezuela1.

When I worked for Schlumberger, it was my job to determine if production casing should be set by running tools in the hole. The measurements produced records called well logs that gave us information about not only the rock below but whether it contained producible oil or not. Drilling is a chancy business, not for the faint of heart. Most wells never produce a drop of oil. I have seen many an owner of a wildcat well near tears as he realized from the logs that the well was a “duster”. That has changed to a great extent in the new-world order of gas and oil production through fracking. The new targets — usually oil shales — were discovered decades ago by previous drilling. They were ignored because shales do not naturally flow under the pressures at depth. Shale is very porous but not permeable. You need permeable rocks to produce oil and/or gas, or so it was thought.

That was before Mitchell Energy, a midsized exploration and production company, drilled the S. H. Griffin #4 well in North Texas into the oil- and gas-rich Barnett Shale in 1997. They used fracking techniques to produce large quantities of methane gas from what was traditionally seen as non-producible rock. If you are interested in more of the details, read Gary Sernovitz’s immensely entertaining and witty book The Green and the Black2. Sernovitz, even with ties to the petroleum industry, takes a rather neutral approach to adjudicate the brouhaha over fracking. One of the highlights of the book is his look at the impacts of the new United States gas and oil reserves on the political and economic scene.

The S. H. Griffin #4 not only produced gas, it produced it in steady quantities (1.5 million cubic feet per day). So how does fracking make an otherwise impermeable rock produce as if it was a well at the height of the oil boom of the 1960s in the United States? Fracking sounds ominous and sinister and conjures up visions of rock being fractured all the way to potable water zones. But it is nothing of the sort — pure fiction. The technique took decades of testing and experimentation in wells to develop. The secret is hydraulic pressure from fluids injected into the well to cause the shale to fracture. The fracturing is usually limited to about 300 feet in an outward radius around the drill hole. And don’t forget, the drill holes typically go down for thousands of feet below the surface and are protected with cemented casing that has only been perforated in small sections usually at the bottom of the hole where the target rock exists.

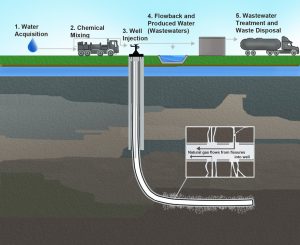

It did not take companies long after fracking became successful to incorporate horizontal drilling, another United States technological advance, into the new smorgasbord of production proficiencies. With the ability to target a bit within inches of a desired location, drillers learned how to gradually arc a pipe into the horizontal (see image below). The technology turned out to be a bonanza when combined with fracking. Companies drilled and set casing directly within and parallel to the oil shales enabling them to frack large sections of the rock which sent production through the ceiling.

EPA

EPA

The chemicals used in fracking were originally a trade secret, but people talk, and once the word was out, companies like Halliburton published the composition of their fracking liquids. Turns out 90 percent of the frack is made up of water, 9.5 percent consists of a proppant which is usually sand, and only 0.5 percent consists of the scary chemicals often used to undermine the industry. The sand serves as a support to keep the fractures (caused by the pressurized fluid) propped open so gas and/or oil will flow. I am not going to pull punches here. It takes a lot of water to frack a well. Sernovitz estimates that a typical frack (an average of 22 stages) uses between 4 and 8 million gallons of water and about 6 million pounds of sand. Unfortunately, not all of the fracking fluid stays in the hole. Some resurfaces. Today the water that comes back is reused or disposed of by pumping it into former producing fields in a concerted effort to make sure the chemicals within the water (even if they are only 0.5%) are placed out of harms way.

It has been widely reported that fracking causes earthquakes. Actually the disposal of water being pumped into the ground (usually from fracking) causes the seismic activity. Perhaps it seems like a trivial difference, but the public seems to have the idea that the pressure from fracking is so great that it directly causes earthquakes. The typical increase in seismic activity in a state like Oklahoma is usually effectively mitigated by diverting the injection of water from fields responsible for the activity or requiring the water to be disposed of via other methods. There can be little doubt that the earthquakes are associated with well injection and regulatory commissions need to fully address the problems.

The HBO premier of Gasland, a 2010 documentary about the natural-gas industry in general and fracking in particular, was probably responsible, at least in part, for New York State banning fracking and a great deal of misunderstanding about natural gas and its impact on the environment. I have two conflicting opinions about the documentary by Josh Fox. 1) It is clearly tarnished with misrepresented science, almost hysterical overreaction, and historical inaccuracies. The documentary has been thoroughly taken to task by Energy in Depth. 2) Having said that, there is no question that it is emotionally moving. It was difficult to watch people whose lives have been impacted badly by the failures of the gas industry. My conclusion — Gasland was necessary to open a national debate about the issue which has led to more government oversight and less rogue shortcuts leading to serious problems. However although there will always be problems associated with any industry, drilling for natural gas and/or oil on land in the United States is relatively safe to groundwater. We simply have to make sure that casing practices are properly implemented. Water taps catching fire in Dimock, Pennsylvania, happened because of sloppy cement work and poor casing in 27 holes during the early days of drilling in the State (gas leaked through the casing into the surrounding water table). I find it reprehensible that companies would not protect the water table at all costs and fully agree that the companies cited deserve the penalties they received and payouts they had to make to people they injured.

Finally, I need to emphasize that in 2015 the Environmental Protection Agency (EPA) did a summary paper entitled Assessment of the potential impacts of hydraulic fracturing for oil and gas on drinking water resources and concluded that “Assessment shows hydraulic fracturing activities have not led to widespread, systemic impacts to drinking water resources”. We can conclude that the gas industry has made mistakes, but we cannot contend that our drinking water is in danger because of fracking despite claims to the contrary in sources like Gasland.

Let’s not forget why Fox started filming the documentary – to protect his vacation home in a pristine part of Pennsylvania near the border with New York. I get it. No one wants a drill rig in their back yard even if it is only there for 40-days worth of drilling. By the way, if you want to read a reasoned and enlightening book about how people are affected adversely by drilling, I recommend Seamus McGraw’s The End of Country: Dispatches from the Frack Zone3. He weighs the potentially bad impacts of drilling with a healthy dose of understanding that gas and oil companies are filling a demand created by the United States and other world consumers. Unfortunately, Fox never examines the financial impacts of shutting down the fracking industry.

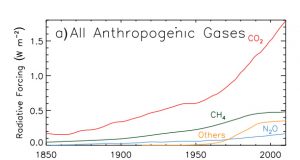

I recently wrote an article on the serious implications of global warming particularly related to the increase of athropogenic gases in our atmosphere. Of the three major fossil fuels, coal is, by far, the worst polluter of carbon dioxide followed by petroleum. Natural gas is the least (see figure below showing the effects of anthropogenic gases as radiative forcing). In fact, Sernovitz has emphasized that “the United States has led the world in carbon dioxide emissions reduction because of shale gas [use of methane gas instead of coal]”.

IPCC Fifth Assessment Report 2013

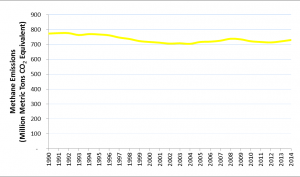

It would be unfair not to point out that methane leaks into the atmosphere directly from the production of methane gas contributing to anthropogenic gases (as methane) also, but according to the EPA in a report entitled Overview of Greenhouse Gases: “Methane (CH4) emissions in the United States decreased by 6% between 1990 and 2014.” During the period from 2007 to 2014, natural gas production was increased tenfold according to the US Energy Information Administration database. The EPA goes on to comment that “During this time period [1990 to 2014], emissions increased from sources associated with agricultural activities, while emissions decreased from sources associated with the exploration and production of natural gas and petroleum products.” Note the lack of effect from the natural gas boom between 2007 to 2014 in the graph below showing total United States methane emissions (converted to carbon dioxide equivalents). In a paper funded by the green-friendly Environmental Defense Fund (EDF) and published in the Proceedings of the National Academy of Science, Allen et. al4 estimated from measuring 190 onshore gas locations that about 0.42 percent of the methane produced leaks from drilling and completion of the wells. The EPA is working with the gas companies to further reduce this figure but, once again, it is hardly having the impact sources such as Gasland have portrayed.

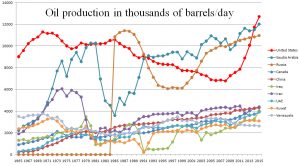

The oil production in thousands of barrels per day since 1966 from the top ten oil producing countries (as of 2015) is shown in the diagram below. One of the most startling aspects of the graph is that the United States has become the World’s largest producer of oil. It’s not Saudia Arabia or Russia, it’s the United States. What is even more remarkable is that our world lead came through good old fashion American know how — the technology that enabled the United States’ producers to frack horizontally. I am no flag waver, but there is no denying how the United States has transformed itself. The halcyon days of the 1960s when the United States led production worldwide were thought to be gone forever (see figure). By the early 1980s, even secondary recovery processes in declining oil fields could not up American production. Our decline in oil production continued until about 2005 when fracking began to be felt. The dramatic impact of that technology can be seen by the subsequent rise in production for the last 10 years in the graph below. However, our increased production does not meet our ever-increasing demand, but it not only helps our trade deficit but decreases our dependence on oil from the troubled Middle East and a hostile Russia. Along with the increase in oil production, we have also become the world’s leader in the production of natural gas (don’t forget that both oil and natural gas have less impact on climate change than coal).

I asked Gary Sernovitz what he thought about America’s new role as a leading oil and natural gas producer: “One of the strange things about the gas boom is that even as prices have gone down, and activity has gone down (because of low prices), volumes have still gone up—a credit to how productive have been [sic] the wells in the Northeast US. This year [2016] gas production is down slightly, but we’re still producing 34% more than the Russians so no risk of losing our crown. 2015 was the year that we exceeded Saudi Arabia in total oil production, and became the world’s largest oil producer. We’ve temporarily lost that crown in 2016, but I’d expect [our] prices to recover for that leadership to happen again soon. And I do think we’re still by far the largest oil and gas producer, despite the dip in oil production because of prices, as we’re far ahead of Russia on oil now too.”

So I would like to summarize the article by stating categorically that we need to curb anthropogenic gasses (carbon dioxide, methane, etc.). But attempting to shut down the oil and gas industry in the United States because of fracking and/or to solve the climate change problem is like trying to take out a drug cartel to stop drug usage in the United States. The only way we are going to reduce our dependency on oil and gas is to reduce the increasing need for it. Fracking is relatively safe to the consumer and looks to be giving America another chance to remain less dependent on other suppliers while we find alternative sources to replace or at least curb America’s craving for energy.

- Margonelli, L. (2007) Oil on the Brian: Adventures from the Pump to the Pipeline: Doubleday ↩

- Sernovitz, G. (2016) The Green and the Black: The Complete Story of the Shale Revolution, the Fight over Fracking, and the Future Energy: St. Martin’s Press ↩

- McGraw, S. (2011) The End of Country: Dispatches from the Frack Zone: Random House ↩

- Allen, D. T. et. al (2013) Measurements of methane emissions at natural gas production sites in the United States: Proceedings of the Natl. Acad. Science: 110, 17768–17773 ↩

Asbestos Wikipedia

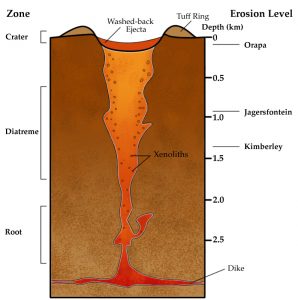

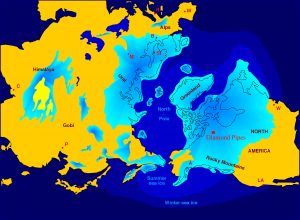

Asbestos Wikipedia Base map from Wikipeida

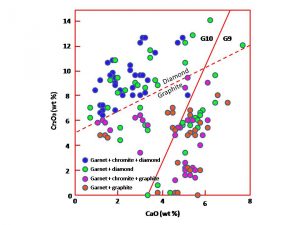

Base map from Wikipeida After Nowicki et al., 2007

After Nowicki et al., 2007 Esker in Sweden (Hanna Lokrantz Wikipedia)

Esker in Sweden (Hanna Lokrantz Wikipedia) Ekati mines from the air (Google Maps)

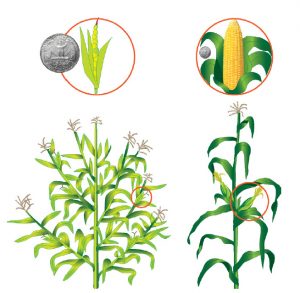

Ekati mines from the air (Google Maps) International Rice Research Institute (IRRI)

International Rice Research Institute (IRRI) NAS

NAS NAS

NAS